How to Determine the Number of Layers in a PCB? Steps & Factors Determining PCB Layers!

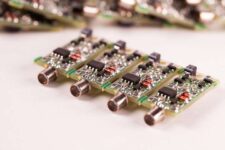

Several different types of printed circuit board assembly would like to meet the product’s needs, including single-sided, multi-layer, and even flexible boards. These circuit boards indeed have a unique number of layers that add to their design, making them suitable for various tasks. It can be challenging to determine the layers in a PCB, but we’re here to help you learn the basics so you can determine the number of layers in a PCB! A printed circuit board may have a single layer of dielectric and several layers of conductive materials. As these layers are connected, they bear electrical circuits that are often related. Printed circuit board distribution design determines the number of layers and their dimensions.