Almost since day one, one or another type of PCB was a necessary component in electronics. Earlier, it was used as mechanical support, where electronic components were attached and wired separately. Later from being only mechanical support, PCBs started providing electrical connectivity. Modern rigid PCBs are more than mechanical support and connectivity. They can integrate electronic components such as antennas, inductors, resistors, and capacitors. Modern PCBs are designed to spread thermal energy to keep parts cool. In some cases, PCBs are used as design elements, front and back panels. Rigid PCBs dominate because of their manufacturing simplicity, low cost, and high demand.

Modern electronics have changed significantly due to the increasing demand for small, sophisticated, and efficient devices. Small devices tend to have weird shapes and are packed with loads of electronics, whereas conventional rigid PCBs fail to fill this niche as they cannot be bent or layered on top of each other without increasing the thickness of the device size. Earlier flex PCBs were used moderately in a limited number of applications due to increased expenses of limited manufacturing capabilities. You could see flex circuits on cameras and some phones. However, things changed once developers saw the potential of small, lightweight electronics. Manufacturers have made a significant effort to develop complex flexible and yet durable PCBs that can withstand harsh industrial conditions where temperature, pressure, and chemical conditions occur.

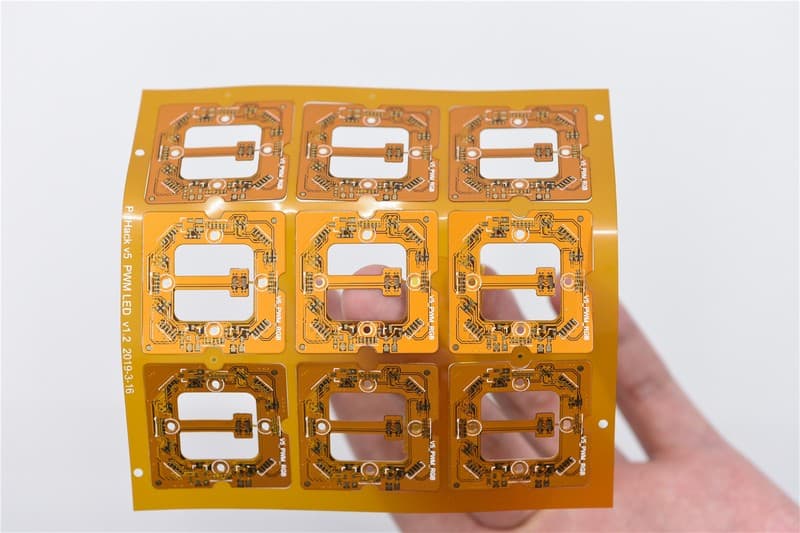

What is Flex PCB?

As the name implies, flex PCBs are flexible and can be bent to some level. Instead of using rigid material like FR4, flex PCBs are based on a thin PET or Polyamide film. Similarly, flex PCBs can be single, double-sided, and multilayered to rigid PCBs. Flexible material allows it to be folded into complex shapes that can fit into complex volumes of small devices. Flex PCBs enable electronic devices to be sculpted into natural and organic shapes.

Designing and building flex PCBs is still more costly than rigid PCBs. The manufacturing process requires more human interaction, additional materials such as stiffeners may be required, copper thickness also may vary in traces and connectors. However, in the long run, and large volumes, flex PCBs may become the more economical solution, as it requires fewer interconnections, many areas can be accomplished with single PCB rather than stitching multiple smaller ones.

The most common advantages of Flex PCBs are:

- They can be bent, transformed into any shape to fit specific enclosures

- Easy install as most of the components use flex connectors and snap connectors

- They can withstand higher temperatures and harsher environments than rigid PCBs

- Higher resistance to vibrations

- They are lighter and thinner to fit modern wearable and consumer electronics

- Being initially more costly than rigid, they can get cost-effective due to lack of multiple connectors

There are also several disadvantages of Flex PCBs:

- They are less resistant to static electricity

- Risk of overbending

- Risk of tearing

- Near to impossible to repair

- Increased initial cost

- Harder to automate manufacturing and assembly

No matter how good it sounds, flex PCBs alone is rarely used.

Rigid-Flex PCB tandem

As most electronics components are rigid, soldering complex circuits on the flexible surface is not a good idea. It is hard to ensure proper solder joint quality, especially for more significant components. Additional stiffening on circuit areas may help; however, only smaller footprint components are soldered on flexible regions. For more complex circuits a, rigid-flex PCBs are used, where electronics are soldered on rigid parts of the board, and flex areas are used for connectivity.

The advantages of using Rigid-Flex PCB technology:

- It gives enough flexibility to fit the board into the device while maintaining the ability to bend and twist

- Reduced weight because rigid parts are used only in circuit areas

- It is designed without solder joints and connectors to increase durability and reliability

- It can withstand high temperatures and extreme conditions better than rigid-only boards due to the polyamide layer

- Less material required for assembly

- Better shock and vibration resistance

Disadvantages of Rigid-Flex PCBs:

- All the inherent problems from Flex PCBs, as discussed above

- The fragile connection between rigid and flex parts

- Complex design and manufacturing

- Humidity may result in delamination

No matter all advantages, manufacturing of Rigid-Flex PCBs is more challenging because the designing process is taken to three-dimensional space. Also, several specific design rules must be followed when designing flexible and rigid parts. Let’s, go through several standard rules that need to be followed to design and build successful Rigid-Flex PCB:

- Place electronics components on rigid areas. Unless this is necessary, electronic components should be soldered on rigid parts to avoid tombstoning. This also allows having fewer layers of the flexible part.

- Traces should be distributed evenly in the flex part. Distributed traces allow getting better signal integrity and overall strength.

- Trace geometry should be constant in the bending area. Twisting and bending might impact the material’s physical properties, so be sure that bending and twisting impact all the same traces way. Keep traces round in bending areas to reduce the chance of tears.

- Avoid blind and buried vias in flex areas. This is an unnecessary complication for manufacturing. Also, blind or buried vias may bring problems due to detachment inside.

- Avoid sharp trace transitions near connectors and solder joints. Use a gradual transition from wide to narrow traces. This prevents the chance of tears and weak points.

- In multilayer flexible PCB areas, try to offset traces on opposite sides to achieve better mechanical properties and cracking chances.

- Pads on flex PCB should have more copper area for better strength.

- Avoid solid polygons on flex areas. The hatched filling is more flexible than a solid pour.

Typical applications of Rigid-Flex PCBs

There are lots of benefits of using flex or rigid-flex PCBs. Extreme versatility comes with increased cost. Designing and manufacturing Rigid-Flex PCBs is more expensive and usually pays off in massive production or exceptional cases where a higher price is not the primary factor. They are common in military, aerospace, automotive, and medical applications, but recently they have appeared more frequently in commercial products. Here are several circumstances where Rigid-Flex PCBs are an optimal solution:

- High-shock and vibration environments. Due to the flexible part, PCBs are resistant to shock and vibrations. Industrial machinery, scanning heads, spinning devices are the elements where rigid-flex PCBs are a cost-effective choice.

- Areas where connector failures would be fatal. Aeronautic applications, space, or military demand on reliable electronics. If a simple connector failure between PCBs would bring significant consequences, the choice of Flex-Rigid is obvious.

- High-density electronics. Sometimes it is hard to put lots of electronics in tight spaces. As an example, we can use satellites. It is very limited in size and weight, but high demand for high functionality and redundancy is high. Rigid-Flex PCBs allow reducing the number of connectors, board sizes, and weight significantly.

- Devices that require multiple rigid boards. Each board needs to be interconnected reliably and cheaply. A cost-effective solution is to use a single Rigid-Flex PCB to reduce cost and fit organically.

Rigid-Flex PCBs are ideal in significantly reducing the number of required connectors. This leads to less labor in assembly, better reliability in applications.

Conclusion

Many small and intelligent devices such as laptops, smartwatches, and wearables are possible thanks to revolutionary flex and Rigid-Flex PCBs. Reduced size and weight give a new edge to small, multifunctional devices. It appears that this trend will grow soon, leading to more robust and cost-effective manufacturing of Rigid-Flex PCBs.