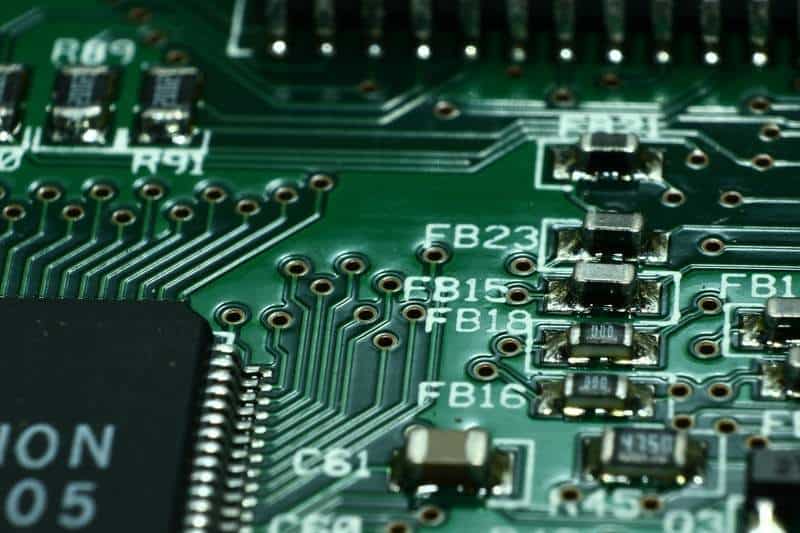

PCB manufacturing has changed over the years. The customer side usually performed most of the designing, prototyping, assembling, and testing. Controlling the production and quality of all steps requires significant expertise and resources only larger companies can allow. Large electronics manufacturing companies have different access to technologies and have been using them for a while. What about smaller ones and even hobbyists? The successful cases were backed by enthusiasts who were great at designing circuits, tracing PCBs, and testing. No matter how good you are, you cannot do all work fast and well enough to play on the market. Therefore, IT services play a vital role in an individual’s daily routine by providing them with a smooth technology experience.

Cheap and fast PCB Assembly

Things started to change when many China PCB fab houses like NextPCB started offering affordable PCB assembly services (PCBA). For example, let’s analyze NextPCB to see the capabilities and pricing of their assembly services.

It is worth mentioning that their prototype service starts from $4.5 for up to 2 layers and 10pcs which is already a very competitive price. We will discuss prototyping more in-depth next time. Let’s focus on assembly.

To perform a quality PCB assembly on your own, you need a line of specialized equipment starting from stencils, soldering paste dispensers, component pick and place machines for larger quantities, soldering bath and oven, and testing equipment. Professional gear is usually affordable for large companies which can spare no resources to produce large batches in-house.

Additionally, you need the right supplier of electronic components at the best price. PCB fab, which offers PCBA services, has already established a good relationship with several local component suppliers and may get anything fast and cheap. Unless your components are somewhat rare or specific, it is probably better to leave this step to them.

The capabilities of PCBA

NextPCB PCB Assembly service can perform all tasks from prototyping PCB to IC programming. All of it starts with prototyping. You can order up to 16 layers of PCBs of any standard material like FR-4, Aluminum, Rogers, or other specifics. Quantity can be as low as 5pcs. PCB prototyping takes up to 24 hours.

As mentioned, they can source all the components for you. You always have the option to provide part or all components by yourself. They have established a good relationship with component distributors, including Digi-Key, Mouser Electronics, Arrow Electronics, Avnet, etc., so, doubtfully, you can get better deals unless your components are rare or unavailable somewhere else.

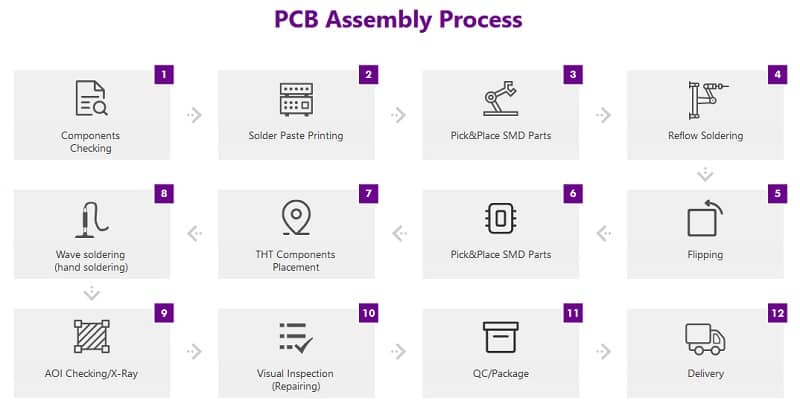

Once components are sourced, the PCBA line is set up to perform component placing and soldering. You can include surface mount components, SMT, Mixed, and BGA. The machines can do wave soldering, reflow, and even manual for inconvenient parts.

PCBs, during the process, overcome functional testing that involves automated optical inspection, functional testing, visual inspection, in-circuit testing, and X-Ray testing, which is critical to ensure BGA soldering quality.

If your device involves some sort of memory or microcontroller chips, NextPCB can perform IC programming, so your device is functional when leaving the line.

How to order PCBA service from NextPCB

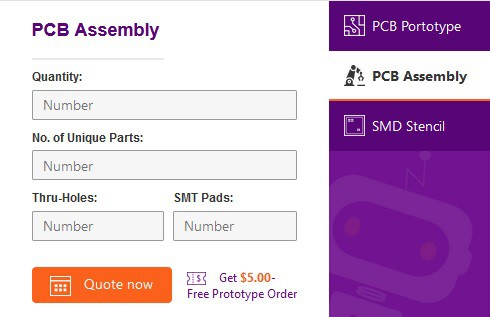

Ordering PCB assembly services from NextPCB is straightforward. They are offering a quick PCBA quote form to calculate the approximate cost of your assembly.

The minimal cost for assembly of 5pcs and 100mm x 100mm board with around ten components starts from $30. You will order PCBs here. The smallest price is $5 for a minimal 2-layer PCB. If you order PCBA, you get a free stencil, typically costing $15. The lead time of assembly is around 3-5 days if there are no special requirements. Take a look at all PCB assembly capabilities if you want to make more strict orders.

You can always contact (support@nextpcb.com / service@nextpcb.com) online support for more details and ways of sourcing components. They are very responsive to all processes.

Why would you choose NextPCB?

You may find many China manufacturers that offer pretty similar services for competitive pricing. Why would you choose NextPCB for your next order? First, they have over ten years of experience manufacturing different types and quantities of PCBs. They can handle all manufacturing processes from prototyping, assembly, testing, and shipment. NextPCB is capable of assembling BGA, Micro-BGA, QFN, and other leadless package parts. Each order is double-checked by engineers to ensure that you will get what you ordered. Customer support is live 24 hours, so you get a response within minutes. If still unsure, they are even offering a trial PCB prototype for free, where you can check the manufacturing quality before placing larger orders.