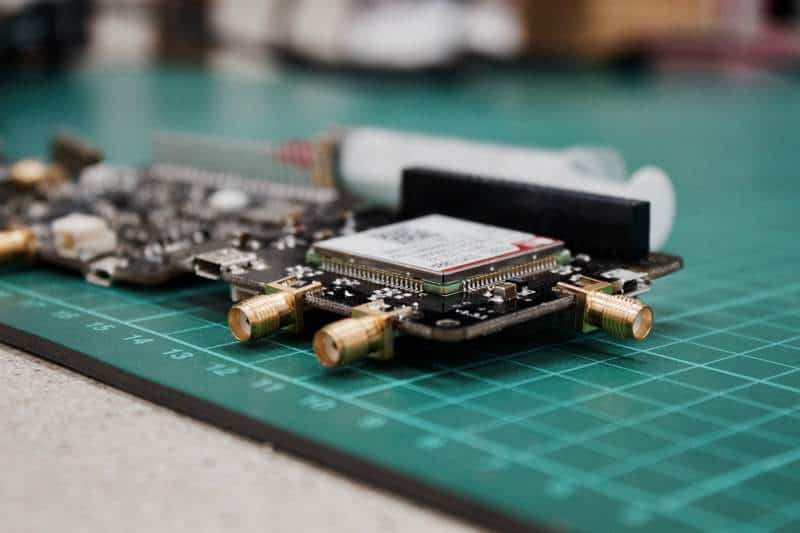

There is not a single electronics device without PCB. It is an essential part which is not usually visible but is an important element of the overall design. Each electronic circuit has to overcome many designing, refining and testing steps until it becomes. Lots of testing is performed to ensure the safety of usage, ergonomics and reliability. The skills of building reliable electronics come with years of experience and constant learning.

Designing PCBs

Manufacturing PCB starts from the idea what electronics device will be used for. The ideas end up with specifications, where functionality, operation limits, controllability and many more features are listed. From this point, circuit design is created. The circuit may be refined many times using simulators, emulators, or even performing testing of different blocks. In this stage, source code can also be created to test the functionality of the circuit. After the circuit satisfies the needs, the PCB layout is created. The process of tracing PCBs requires some knowledge and expertise. There are many design rules, but in reality, most of the time, previous experience plays a significant role. There are places where automatic routine may help, but most critical parts are usually done by hand. Great looking and functional last PCB prototype may overcome several revisions until it is suitable for use in the device.

Not long ago, it was common practice to prepare circuit board design files and send them to the manufacturer. On the one hand, you have total control on how PCB is designed, on the other hand, to make excellent PCB experience and knowledge is needed. This is why fab houses start taking care of the design, prototype and PCB assembly process.

Full-spectrum PCB manufacturing at PCBWay

PCBWay is offering all services related to PCB manufacturing, including designing the board from specs, prototyping, assembling and testing. In such a case, you may have no clue how the process works, but at the end of the day, get the implementation of your idea. No surprise, because PCBWay team is highly experienced in each stage. They are getting over 2000 orders to process, have more than five factories, and more than 500 staff. They ensure that you get what you ask. Let us go quickly through the most common services and minimal pricing.

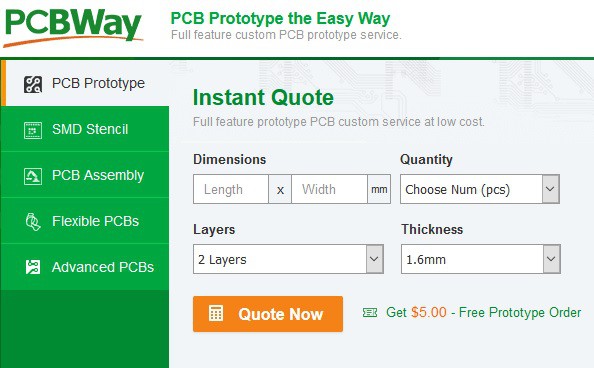

PCB Prototyping

One of the most popular functions of PCBWay is to manufacture PCB prototypes. They have prepared a convenient and functional PCB prototyping quote form on their website, which allows selecting lots of parameters to meet design specifications and personal preference.

Among multiple options, we can mention several, including board size and quantity. For instance, ten pcs of 2-layer 50x100mm are as cheap as $5 without shipping cost. And manufacturing is finished within 24 hours. Other parameters include board thickness, solder mask and silkscreen colours, surface finishing, copper track thickness, way of panelisation and number of layers with different processing of vias. If you select different than the default option, you should already know what you are doing and be prepared to pay more as these involve nonstandard operations that stand out from the normal routine.

You choose different base material other than standard FR-4. Depending on the selection you are opted in to even more options. Common advanced materials are:

- Advanced Rigid PCB technologies. Used for high tech and quality boards. For

instance,/HDI/Rogers/High-Tg technologies are meant for high-frequency

electronics, automotive and other particular purposes. Choosing those boards may

require a different level of expertise in designing and assembling PCBs. - Aluminum PCBs. Two types of aluminium PCBs – central and base

core are possible. The choice depends on the desired power, dissipation

properties and mechanical stability. - Copper PCBs. Similarly, to aluminium, copper is used for better thermal performance

and other specific properties leading to a higher cost. - Flexible PCB. They are commonly used in nonstandard type portable devices or

miniature electronics such as smartphones, cameras or smartwatches. They allow

squeezing complex circuits in tight spaces. - Rigid-flex PCB. This technology joins flexible and rigid PCBs

into a single unit without additional connections between them. In such a way, manufacturing

becomes easier and cheaper with the benefits of both technologies.

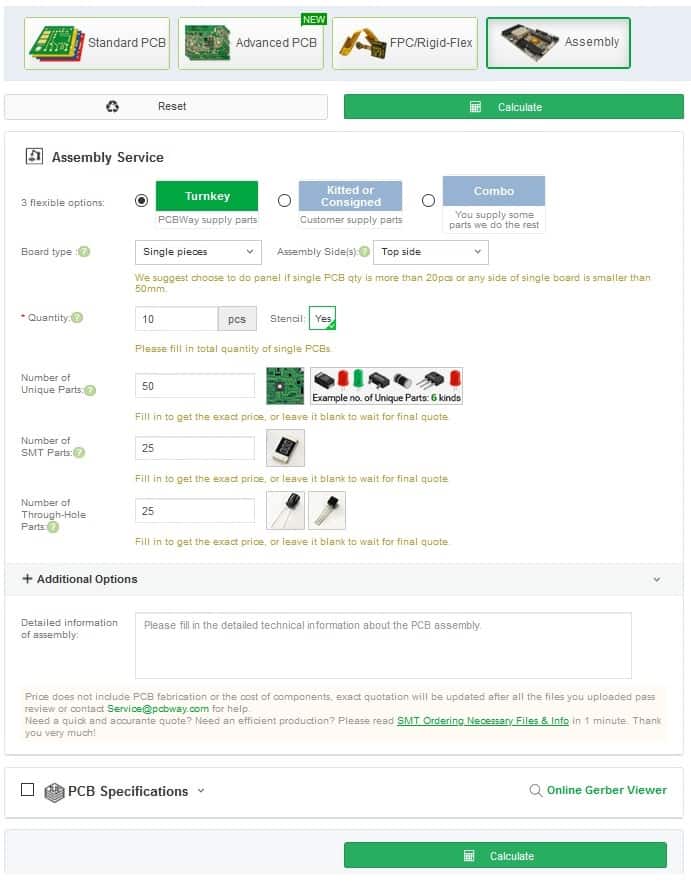

PCB assembly

PCB assembly has never been so cheap. The pricing of assembly services on PCBWay is attractive and competitive amongst other manufacturers. An online quote form helps to make a rough estimation of the approximate cost of assembly.

Amount of 10 simplest PCBs, with either single or both sides placement with about 50 mixed parts may cost as little as $30. Keep in mind that price includes the only service the purchase of electronics parts also needs to be covered after review. Imagine how much time and preparation is required if you decide to perform PCB assembly locally. Assembly also involves the preparation of stencils which is a free option here in PCBWay. The meeting also is tested functionally and passed through X-ray inspection to ensure soldering quality. The turn times may be as quick as 24 hours, depending on board complexity and parts required. Here are a few benefits of PCBA:

- The low

price. You cannot beat it by

any means. PCB fab has well-established equipment and professionals that enable

produce a high volume of products for cheap. - Fast PCB

assembly turn times. In many

cases, machines are already ready to lay down and solder essential parts on

board. This is why sometimes your PCB may be accomplished within 24 hours. - Free PCB

stencils. In case you do

assembly and soldering on your site, – stencils may bring additional cost. - The

sourcing of electronics parts falls

on fab, and they have more essential deals when purchasing components from

reliable sources such as Digi-key and Mouser and usually in high volumes. - High

quality of PCBA. Assembly and

soldering are passed through quality control by performing functional and x-ray

testing. They have equipment and team to go through this critical step. - PCBA

saves time. The time you would

spend assembling, and testing boards can be spent on other activities and

developing new ideas. Saving time and money is the most significant advantage,

especially in a small business.

However, PCB assembly service takes most of the control during the process. In case of too late spotted errors, it can be tricky to make tweaks. Also, you have limited control of sourcing electronics parts. Usually, the manufacturer has excellent sources and deals you wouldn’t get by yourself.

PCB design service

In case you or your company doesn’t want to spend time and resources on creating design files, you can deliver rough specs, and PCB design services take over.

The PCBWay are incredibly flexible and can do many things, including:

- Electronic

design, including technical project management. - Financial

management of the project. - Software

and Firmware programming, implementation, and IT management. - Mechanical

design of the project, including 3D modelling and realization. - Documentation

from start to finish.

PCBWay is capable of taking care of all product development steps: design, prototype and assembly. Design service may require the most significant investment. Still, in the long run, it may save lots of time and money as a process involves highly experienced professionals leading to fewer errors and delays. Check out the other capabilities of PCBWay fab house.

Bonuses from being PCBWayer

If you follow them long enough, you may see, that PCBWay is always running festivals, giveaways, challenges and shows. It is still a great chance to earn bonus points (Beans), that converts into currency which can be spent on the gift shop. Since the whole world is suffering from COVID-19 virus, PCBWay includes a pack of 10 free masks in each order until they run out of approx. 100k.

Additionally, each order also comes with a small gift from the gift shop. Don’t hesitate, make an order to save money and time. Be safe and productive!