Topics of this article: AUTOSAR, embedded non-AUTOSAR, layered architecture, scalability, software development.

AUTOSAR – the beginnings

Since 2002, starting with the conception of the AUTOSAR standard, the way the automotive industry collaborates has drastically changed. Its improvement is still ongoing in order to provide higher performance in the automotive industry. In the embedded world, the standard has become a must for those who want to align and have a chance to compete with the best of this industry.

Standardization of specific exchange formats

Tier 1 manufacturers have a lot of benefits using the standard because they save the time invested in understanding the specific formats or requirements of other manufacturers. Through AUTOSAR, the content of requirements and formats are heavily standardized. Therefore, tier companies speak the same language, a fact that reduces lead time and improves productivity.

“Therefore, tier companies speak the same language, a fact that reduces the time and improves productivity.”

Layered architecture

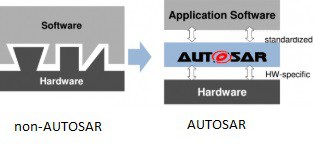

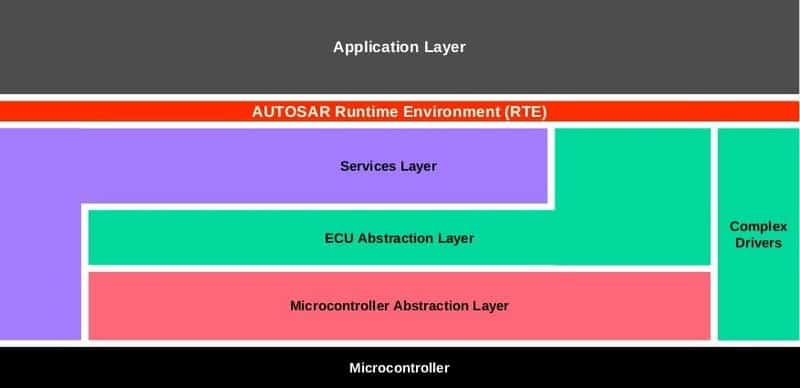

The layered architecture ensures that any change will have the most negligible impact on the project. Just imagine a non-AUTOSAR project, that, during development, needs to have the microcontroller or another hardware component changed. Almost all the created software will suffer changes, plus these changes will require a lot of invested extra time to make the project functional again.

But, using AUTOSAR, thanks to its layered architecture, the only impacted layer will be the one that interacts directly with the microcontroller. Hence, only the Microcontroller Abstraction Layer will need re-design.

Software Component Re-Usability

Using AUTOSAR, the software components are completely independent of the hardware.

Using AUTOSAR, the software components are entirely independent of the hardware. In other words, the application doesn’t need to know where the dependencies and inputs come from; it can be reused in any other project multiple times, saving a lot of time and money. Without this standard, the software components must be re-developed by the underlying hardware every time.

Standardization in matters of interfaces

Given that a big project is composed of several complex software components, the easiest way to implement it would be to use the AUTOSAR standard.

If a new software component needs to be added, using the standard, the focus will only be on implementing the inside algorithm, without adapting to the OEM environment.

Standardized interfaces will simply connect our newly added software component with the existing project.

Scalability

Standardization, the layered architecture, and reusability together make room for scalability.

In conclusion, AUTOSAR makes the software more scalable. This is especially important when it comes to systems with high potential for growth and change.

The benefits of using the AUTOSAR standard in our projects, will not only save time but also money. Above all, it will save us the energy we need to act more innovatively, to perform better with our products.

Stay tuned; a new article is coming up soon, about the importance of layered architecture. Also, please find out more about what we do when it comes to embedded, here.

About the author

Dorin Lapadat is a technical lead on complex embedded projects and an expert in implementing the AUTOSAR standard, he is working in Automotive Engineering & IT outsourcing.