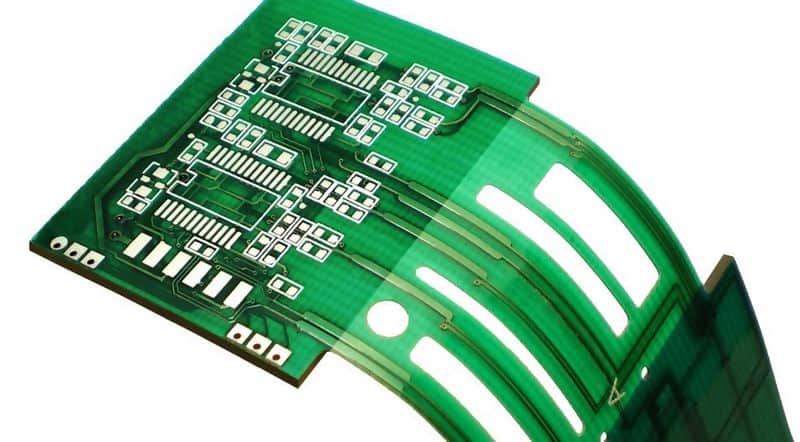

1. What Is a Flexible Circuit Board?

A flexible circuit board is a PCB specially designed to be flexible. Flexibility is the essential feature of these boards, and it is the reason why they are becoming so popular.

Flex PCBs have a wide application field, including but not limited to:

- Smartphone

- Automotive electronics

- Computer electronics

- Industrial applications

- Medical field

- E-commerce

You can use them wherever you need adaptability from the circuit board. If you realize that you require a bending circuit during the assembly process, flex PCBs will be the ideal solution.

Special Manufacturing Processes

Flexible printed circuit board manufacturers use two different processes when designing a flex PCB:

- Subtractive – in the beginning, you have a whole piece of metal, and then you remove (subtract) the unnecessary part. Screen printing and photo imaging assist in defining the pattern of the circuit. The creators prefer using this approach since it is more affordable and allows plenty of freedom in configuring the board.

- Additive – here, the designer has only a bare dielectric layer in the beginning. Forming the circuit is the ultimate goal, and the creator adds metallic traces wherever it is necessary to do that.

Ultimately, the manufacturers use surface finishing to ensure that flex PCBs are ready for future bonding.

Advantages and Benefits of Flexible Circuit Boards

- Reliability and durability – you get a long-lasting product that will deliver consistent performance.

- High-temperature applications – as long as you go with reliable, flexible printed circuit board manufacturers, you will be sure that their product can withstand high temperatures.

- Completely flexible and pliable – if you can’t avoid warping or bending, these boards are your best choice.

- Can accommodate any design – you can demonstrate maximum creativity and pursue the preferred design knowing that the board can provide it.

- Component/connector assembly – flex PCBs are suitable for any connector or component used in rigid board design.

- Package size and weight reduction – thanks to flex boards, you can decrease the overall size of items.

2. Factors to Consider a Flex-PCB Manufacturer

Before you can move to choose the right manufacturers, let’s make an overview of the factors you should consider in the process.

Risk Factors

You should strive to find flexible printed circuit board manufacturers that put in maximum effort to ensure maximum accuracy and decrease potential risk factors that may lead to the board’s failure.

Key Design Factor

The experts suggest that the critical factor the creators should apply is ensuring the optimal distance between the center of the material stack and the neutral bend axis. The goal is to keep the length as short as possible to enable even distribution of forces when the PCB is flexing.

Some other risk factors are:

- Bending it too much (keeping the angle low is better)

- The thickness of the PCB – thinner boards are better

- Inadequate materials – it is always essential that the manufacturers use materials of premium quality

Environmental Factors

While we are on the topic, let’s mention that environmental factors can also lead to the failure of a flex PCB. Here is the list of items that can increase the risk of damage:

- Humidity – water and moisture can lead to a shortage if they cross board’s channels. High levels of humidity can lead to mold, which increases damage risk, too.

- Dust – it can decrease the capability of the board to keep optimal temperature by preventing heat dissipation. That can lead to overheating and destroy the unit.

- Extreme temperatures – both heat and cold can damage circuit boards. Cold leads to condensation, while heat can lead to unwanted warping and ultimate destruction of plastic or metal parts of the PCB.

- Static electricity – the experts strongly recommend avoiding any static electricity when the board is in use as it can lead to series damage. That means you shouldn’t have carpets or fabrics that can create in near your board.

- Liquid and gaseous chemicals – some fumes can lead to corrosion, and even cleaning solutions may cause damage to the unit.

Factors to Consider When Selecting a Manufacturer

Now that you know potential design flaws and risks, you know what to be mindful of when selecting and using a flex PCB. Now, let’s take a look at some tips you can use when picking from the available flexible printed circuit board manufacturers:

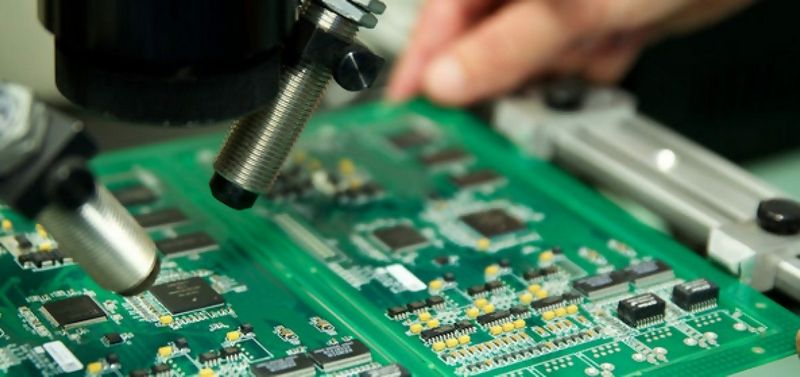

- Manufacturing capabilities and processes – you want to ensure that the manufacturer has the right type of equipment to fulfill your demands and expectations.

- Is the experience rich? – the company needs to provide outstanding customer service and be ready to answer any question you might have.

- Lead time and delivery time – you should make sure that they can complete the order in the shortest possible timeframe, as well as deliver it as soon as possible.

- Quality – the product you receive should be of the highest quality to ensure that you made a smart investment.

- Price – it is only wise to consider the price, too. The main objective should be that you get an excellent value for the cost.

- One-stop turnkey service – ultimately, it is vital to ensure that a single company can provide everything you may need related to flex PCBs.

3. Manufacturing from WellPCB

We searched the market up and down, and we decided to recommend WellPCB. Here is a quick overview of reasons why they are your best choice from all flexible printed circuit board manufacturers:

- An autonomous online ordering system

- Experienced engineers and business managers work in a workshop dedicated to manufacturing flexible circuit boards

- Fast delivery time

Flexible PCB Quote System

Forget about wasting hours or days on sending e-mails back and forth until you get all the details of your order right. WellPCB has an entirely ordering and payment system. Thanks to that, you will save 60% of your time, and you will have the opportunity to save money by utilizing special online discounts.

The ordering process is incredibly convenient and simple. Here is how to place an order:

- Register for an account on the WellPCB website. Do not worry – the process is entirely free, and it won’t take more than a minute or two.

- Select the specifics of your PCB order. You can start with the basics, such as layers, dimensions, and quantity. The system also lets you get into details, such as polyimide thickness, silkscreen color, and the desired stiffener.

- Based on the information provided, the website delivers an instant quote. At this point, you will notice how affordable WellPCB prices are. If you agree with the offer, add the product to the cart.

- Once you placed all desired orders, proceed with entering your address and choosing the desired delivery method. The system will now calculate the total price.

- Head to the checkout and pay with your PayPal account in a couple of clicks to finalize the order.

If you have any questions, friendly customer support is at your service. You can send them an e-mail anytime during the day and expect a quick response.

A Dedicated Team of Experts

WellPCB has a production workshop wholly dedicated to manufacturing flexible circuit boards. The staff has more than ten years of experience in the field and related industries. That experience, combined with their extensive knowledge about PCBs, is the best guarantee that they can meet any request from the client, no matter how challenging it is.

The workshop has a team of dedicated engineers which are supported by skilled business managers. Their task is to organize work in a way that secures that each unit is delivered on time, as well as to ensure the shortest possible timeframe for any project.

Fast Delivery Time

It is only natural that you do not want to wait for your PCBs for weeks or months. Once you place an order, you want it at your doorstep as soon as possible.

WellPCB ensures a fast completion time of 5-7 days and provides a DHL express service that will deliver the product in 1-3 days. Furthermore, some national DHL freight is available at half the price.

Order PCB Manufacturing Service Online Today

Are you ready to place an order for a flexible PCB? In that case, we should tell you a bit more about the current special promotion the company has in place. Buyers can invest $1 to purchase a $100 discount coupon that they can use in the shopping cart on the WellPCB’s website.

Here is how that works – you place an order whose value goes over $1000. You can activate the coupon in the shopping cart when you pass that sum and get your discount. Furthermore, you do not even have to place a single order. You are welcome to combine two or three orders that will have a combined value of over $1000. During the checkout phase, you can pay them together and utilize the coupon to get a discount.

One-Stop Turnkey Service

WellPCB provides everything you might need for flexible PCBs in a single place. That includes:

- Flexible PCB assembly

- Wire harness procedure

- Fast completion of any order you make

Regardless of how simple or complex your requests are, do not hesitate to contact the company today. As soon as you arrange all the details, they will start working on it to ensure the shortest lead and delivery time on the market.

Conclusion

Flex PCBs are exceptional long-lasting units that can make any product better. However, making the right choice between the available online flexible printed circuit board manufacturers is a tricky task.

Fortunately, WellPCB has made your selection easy. They are a reliable manufacturer you can count on at all times. The online quoting system makes the ordering process simple, even for a beginner. Go ahead and give this company a shot – once you try their service, you will keep coming back for more!