The term PCB stands for Printed Circuit Board. It is a thin board made of fiberglass or other laminate material. It is a basic building block of most electronics today. PCB is used to mechanically support and electrically connect electronic components using tracks or signal traces.

However, depending on the number of units manufactured, most PCB assembly units cost between $10 and $50. The price listed above is an approximate estimate that does not include all tools and setup costs. Moreover, the cost of PCB assembly varies greatly depending on the printed circuit board manufacturer. At JLCPCB, the assembly can be free (excluded components) with the coupon you get when ordering a PCB prototype.

How do you calculate the PCB size?

The size of a line may usually be determined by left-clicking on it in most PCB software. The line’s width is displayed on a bar above the layout. Further, to get the size of the board, multiply the horizontal and vertical lines of the box together.

How much does it cost to design a PCB?

There is no fix and final cost to design a PCB. The hourly charge for PCB design is between $90-$145. Turnaround time, technology, software tool selection, and other factors all influence the rate.

How do I print a PCB at home?

Let’s look at creating a PCB for a simple project in this article.

- Firstly, make a circuit board layout printout.

- Secondly, for the Circuit Board, cut the Copper Plate.

- Thirdly, apply the PCB Print on the Copper Plate.

- Finally, transfer the circuit from the paper to the PCB plate using an iron.

What is the PCB density?

The density is the number of traces, holes, and pads divided by the area unit. Obviously, if you require higher density on a PCB, you’ll have to reduce the size of the lines, spaces, holes, and vias and increase the number of layers, connections, and layer routing.

JLCPCB allows PCB tolerances up to ±0.2mm, but if there is no need to push PCB to the limit, it is better to avoid extremes because the tinier traces and tolerances get, the more chance there will be defects.

Can you make your own PCB?

By using good PCB design tools, you can create your own PCB layout. Eagle Layout Editor is the greatest PCB board design software, in my opinion, although Microsoft PowerPoint is a good option for those who want something simpler.

Why do some manufacturers offer less expensive PCBs than others?

- Some manufacturers have developed strong relationships with skilled PCB makers who provide them with a variety of prices. Moreover, they also make the prices more competitive and more appealing. As a result, buyers can place orders at a minimal cost.

- They provide a transparent ERP system that allows customers to interact with the entire purchasing process. Customers will receive the lowest price for PCB manufacturing with this approach because there are no hidden costs in the purchase.

- To serve their consumers, they employ a large number of skilled and experienced engineers. They will provide important guidance on PCB design and production to lower customer costs by providing the lowest prices with the highest quality.

- Some companies offer discounted PCBs regularly. This is a unique service for students and hobbyists who cannot pay the high cost of PCBs. When they place their orders, they will receive a discount.

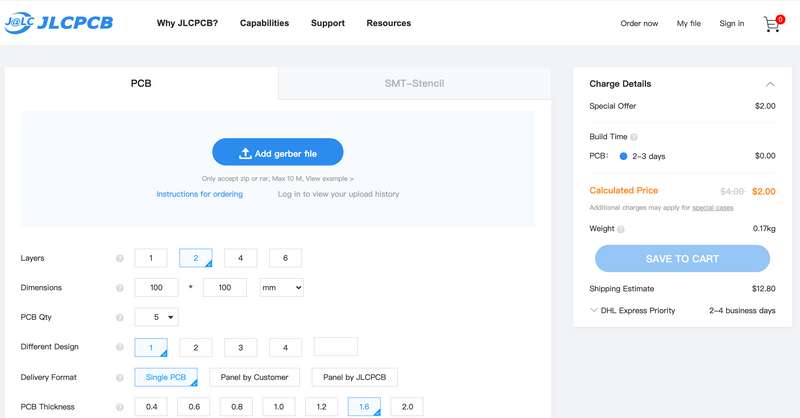

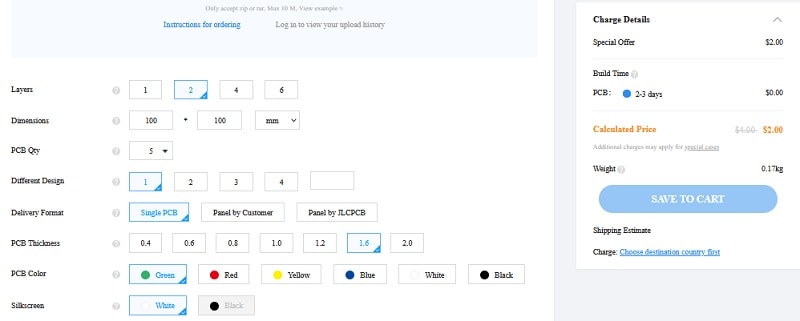

You can check PCB price by using online quote form in JLCPCB:

Why are PCBs so cheap in China?

China’s labor costs are far lower than those of other countries. It is only half the size of some Western countries, such as the United States, Canada, and Mexico. However, this is a necessary component for PCBs to be inexpensive.

Do low-cost PCBs have poor quality?

A low-cost PCB does not necessarily imply poor quality. No PCB manufacturer will jeopardize its reputation by providing a low-cost, low-quality product or service. It all comes down to how a company manages its resources and maintains world-class quality while remaining cost competitive and affordable.

Every designer desires a low-cost PCB prototype. It would be best if you were on the lookout for PCB prototype companies that are economical and dependable. At the same time, the quality of these low-cost PCB prototypes should not be compromised.

Why has the cost of PCBs increased?

The price of PCB manufacturing has skyrocketed. Today’s manufacturers create PCBs using a specific base and solder mask materials to fulfill industry application requirements. As a result, the entire cost of production has risen.

The goal is to keep expenses as low as possible while keeping high-quality requirements. Some companies, such as JLCPCB, are experts in low-cost PCB assembly. Their engineers are aware of the significance of quality and cost control. PCB manufacturers use a variety of methods to reduce PCB assembly costs.

What are the techniques to minimize the cost of PCB assembly?

There are a few methods for lowering the cost of PCB assembly. Some of these are already present.

- Reducing the number of layers.

- Arrange the number of vehicles with care.

- Keep the internal cutouts to a minimum.

- The board is a perfect size for annular rings and holes.

- Choosing the most appropriate route.

- Keep the size of the board to a bare minimum.

- Rather than attempting any unusual shapes, go with traditional board shapes (square or rectangular).

- Only industry-standard components and sizes were used.

- Selecting the appropriate surface finish.

What measures are required to reduce the cost of PCBS?

To reduce the cost of PCBs following measures can be done to each element:

Layer Count:

The cost of PCB increases when the amount of layers is added, because a circuit board has more layers, the higher the cost.

Via Tech:

To build interconnection on a circuit board, vias such as blind vias, funerals, or micro vias play a key role. The number of ways to reduce costs must be carefully arranged.

Size and Shape:

It should be precisely designed so that all functions can be implemented and space is moderate. When necessary, panels are recommended. Small does not lead to low costs directly. The shape also influences PCB prices. Normal forms, such as a square or rectangle, generally lead to lower prices, while special forms are typically more expensive.

Surface Finish:

The surface polish helps provide optimum solderability and electric performance by preventing pads from oxidizing. Different types of surface treatments have their own set of benefits and drawbacks; choose the one that best suits your product’s needs.

Where to buy low-cost PCB in China?

With the efforts of our employees and investments in technology and innovation, JLCPCB expects to be recognized by customers as the main partner in the development of PCB projects.