PRESS RELEASE UPDATED: JULY 31, 2019

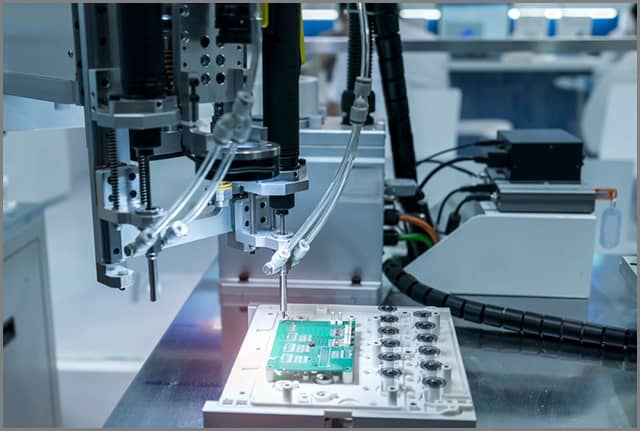

The PCB manufacturing process is an essential part of the electronic product life cycle. Making PCBs is a complex process.

This final guide covers the most critical steps in PCB production.

Just keep on reading to discover more!

Among the key subjects of PCB Fabrication Process include:

- PCB Design and Layout:

This section outlines the precautions for PCB layout, precautions before PCB fabrication, and an introduction to pre-production engineering. - Production Prepare: This section briefly introduces the production preparation process.

- Inner Layer:

- Inner Layer Imaging: This section briefly describes the Inner Layer Imaging consisting of three steps: Inner Film, Inner Exposure, and Inner Layer Development.

- Inner Layer Etching: This section briefly describes the Inner Layer Etching consisting of two steps of etching and unloading the film.

- Inner Layer AOI: This section briefly describes Inner Layer AOI as an automatic optical inspection, To check whether the core plate after etching has an open or short circuit and whether the print is clean or not.

- Lamination: This section mainly introduces the definition of Lamination.

- Drilling: This section mostly introduces Drilling.

- Electroless copper deposition: This section describes the copper primarily in the base plate.

- Horizontal Electrolytic Plating: This section focuses on the copper in the base plate, and the copper in the hole can be thickened to 5-8um by electron transfer reaction.

- Outer Layer Imaging: This section mainly describes Outer Layer Imaging.

- Graphic Plating: This section focuses on the three levels of Graphic Plating, which consists of thick copper plating, tin plating, and film removal.

- Outer Layer Etching: This section mainly describes the composition of Outer Layer Etching.

- Solder Mask: This section briefly describes the role of the Solder Mask.

- Silkscreen: This section briefly introduces Silkscreen.

- Surface Finish: This section briefly describes the part of surface treatment.

- Profile: This section describes the engineering department creating a shape program based on the border provided by the customer.

- Other Surface Finishing Process: This section focuses on the two processes of the Other Surface Finishing Process.

- Electrical Testing: This section focuses on the role of Basic electrical reliability testing and the introduction of Flying Probe Testing.

- Final Visual Inspection (FQA, FQC): This section mainly describes Final Visual Inspection (FQA, FQC) by a professional quality control group for testing.

- Package&Delivery: This section describes mainly the PCB packaging method and delivery time.

Besides, The focus of this article is Let you know more about the details of the PCB manufacturing steps or problems encountered in file generation and how to solve them. Please feel free to contact WellPCB if you have any needs or issues.

About WellPCB

WellPCB focuses on PCB Prototype and PCB Assembly Turnkey Services. All PCBs products are compliant to ISO, UL, and IPC Standard.

Media Contact:

Contact Person: Hommer Zhao (General Manager)

Email: sales@wellpcb.com

Tel: +86-31186935221

Website: https://www.wellpcb.com

Source: WellPCB