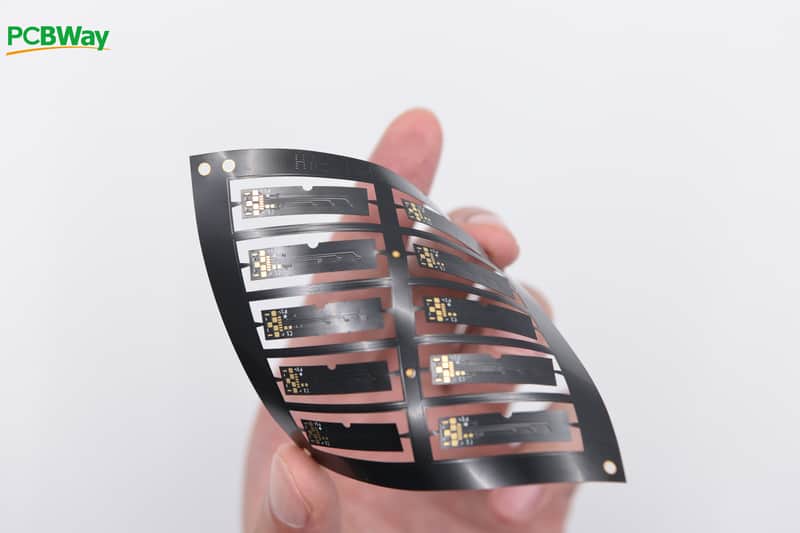

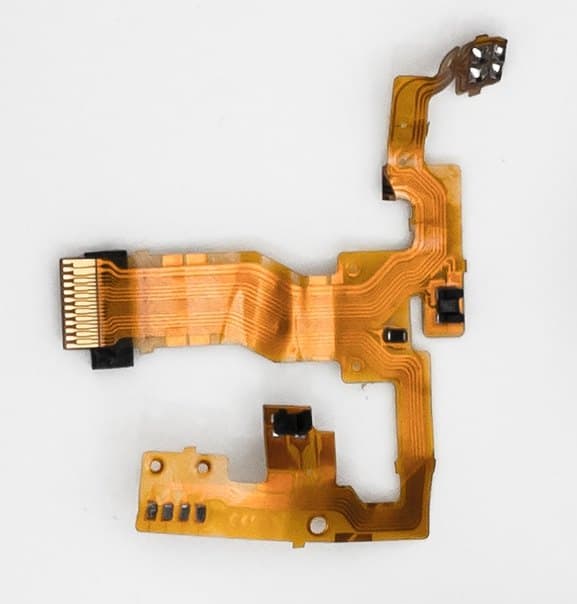

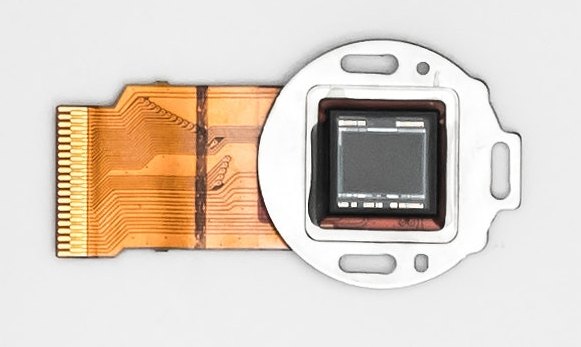

Modern gadgets may have various weird shapes where standard electronic boards may not fit. Cameras, cell phones are possible thanks to flexible PCBs that may take the form of the enclosure and fill awkward spaces in limited areas.

Flexible circuit boards allow designing free-form devices that can be small in size and volume. Flexible PCBs are also a great choice where electronics are in motion or affected by vibrations. As a great example is cameras – such miniaturization and reliability would not be possible without flexible PCBs. Besides, flexible PCBs reduce the overall weight of the devices.

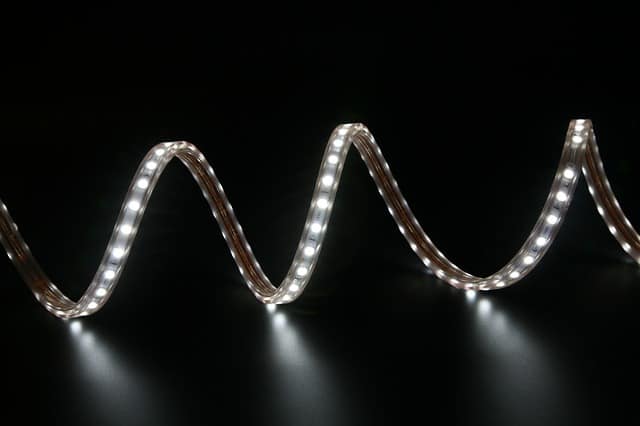

LED strips would be impossible without flex PCB

Only flexible PCB technology allows building long strips of LED belts that can be cut at the desired length, glued to different surfaces and shapes.

Designing the flexible PCBs

The design of flexible PCBs is the same as rigid. You can use your preferred CAD software to design and build it as usual. However, since PCB flexes, you should keep in mind the flexing points and lines and place electronic components so, that they do not intersect the flexing regions.

The primary concern when designing flexible PCBs is the stress points. The design rules differ from rigid PCBs. Surface mount components (SMT) may be stressed because of bending or mechanical vibrations. So additional support through-hole plating may be required in areas where parts are soldered. Traces are also routed perpendicularly in the bending area to increase reliability and reduce stress.

When designing flexible PCBs, you should keep in mind the whole 3D space, how it will be positioned, and according to this, lay the components in the best way. So more complex PCB requires the teamwork of different specialists working with enclosures, functionality, and quality assurance.

Physical parameters of flexible PCBs

Flexible PCBs are similar to rigid where traces are etched copper, but the base is a polymer substrate. Traces may also be printed on the thick polymer film. The mechanical strength depends on the substrate material and additives that may increase reinforcement.

The thickness of the bending areas with copper, gold, or nickel plating may be smaller as more massive traces reduce flexibility.

Flexible PCBs may have multiple layers. They allow designing complex circuits and increase the overall strength of circuits while maintaining some level of flexibility. PCBWay manufacturer is capable of making up to eight layers of the flexible circuit.

The typical situation is when flexible PCBs are mixed with rigid. The flexible circuit is usually connected to a rigid part using through holes.

Key advantages of flex PCBs

We have already mentioned several benefits of using flexible PCBs. Here are few that make them stand out:

- Freedom of design – devices are not limited to rigid PCBs

- Reduced weight – flexible PCBs are lighter, which is beneficial in small electronics

- Requires less space – flexible PCBs can naturally copy the shape of the device, thus occupying less space

- More reliable – better withstand vibrations and thermal stresses

- Require fewer connectors – flexible PCB can be one complex shape without the need to interconnect multiple boards

- Reduced costs – assembly of electronics is more comfortable and less expensive

- Aesthetically pleasing – flexible PCBs look more natural and organic.

When to avoid using flexible PCBs?

If your design size and shape allow – use rigid PCB, there is no need to chase the flexible PCBs. It would help if you calculated the overall cost, and the additional effort of designing the PCB. Despite the better reliability of flexible PCBs, there are many risks of failure.

- Environmental factors – humidity, dust, and extreme temperatures may damage the circuits.

- Static electricity – can do severe damage to electronics. Flexible circuits

- Chemical contamination – chemical fumes can be corrosive.

- Over bend and tear risk – if you bend it too much or tear starts, it may be hard or near to impossible to stop it.

Conclusion

Flexible PCBs bring another level to electronic design. You are not limited to hard flat surfaces but can create new – more organic-looking devices. Flexible PCB technology is not a replacement for rigid, but rather a supplement that may go well together. Flexible PCBs may require additional manufacturing steps, which makes it a bit more expensive. In the end, the overall cost may be even lower as it may require less wire harness and operations.

Not all PCB manufacturers are capable of making flexible PCBs. If you decide to give a try, be sure to research board houses and find the one that offers the best options and prices.

Check out PCBWay options for flexible and rigid-flex PCBs.