Running any business is expensive, and manufacturing businesses are no exception. Keeping a manufacturing business running can be costly, from covering the up-front costs of acquiring tools and materials to regularly paying for electricity and rent. On top of that are the unexpected costs of running a factory – from costly repairs to inventory losses due to sudden weather events or natural disasters. These out-of-pocket expenses can quickly deplete your budget, putting even healthy businesses at risk of closing down.

Saving money is a goal for any business, but because of the reasons mentioned, it’s especially important in the manufacturing industry. It’s more important than ever to find ways to cut costs without sacrificing quality or efficiency. Here are a few of the best ways your manufacturing business can save money while still being efficient:

Use energy-efficient machinery and equipment

Manufacturing businesses must be more energy-efficient to maximize profits and reduce environmental waste. One way to do this is to switch out old machinery and equipment for newer, more efficient models. New equipment often comes with greater output per unit of energy; you may achieve the same production goals or higher with fewer resources. Not only does this lead to a reduced energy bill, but it can also come with other advantages, such as less wear-and-tear on the machinery itself.

You can also consider purchasing secondhand or refurbished machinery in your area, which may offer similar energy-saving options at a lower cost. Manufacturers can find themselves well-placed for a more sustainable future by investing in energy-efficient machines and equipment. It requires upfront capital costs that may not appear in the company’s budgeting. Still, over time those savings will pay dividends while maintaining environmentally friendly standards in production.

Utilize manufacturing automation

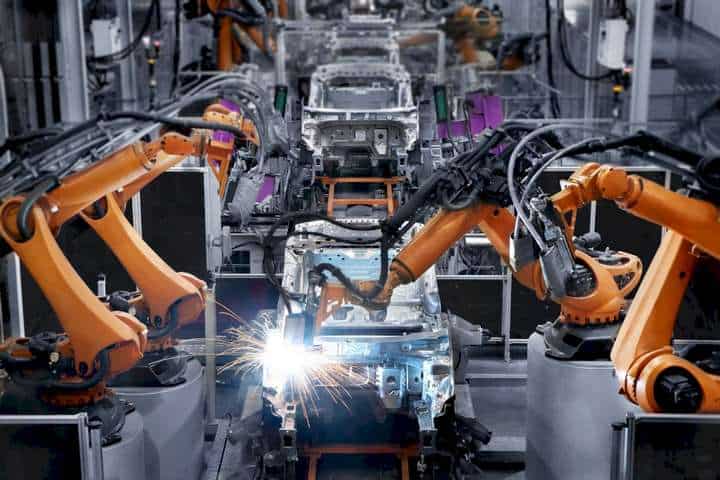

Automation is the future for manufacturing businesses, providing more efficiency and increased production at lower costs. Automation can help streamline all aspects of your business, from inventory to communications, enabling you to be more efficient in your operations. Automation speeds up and simplifies production processes by reducing manual labor and freeing up valuable employee time and resources that can be used on other activities such as problem-solving initiatives or customer relations management.

For example, robotics is a common manufacturing automation that has revolutionized the industry in recent years. Robotics can take over many basic and repetitive tasks, such as moving heavy objects or performing assembly-line tasks, which frees up time for your workers to focus on more important aspects of the job. Additionally, robots can work around the clock without needing breaks or requiring employee supervision, making them an excellent addition to any manufacturing business.

Moreover, automation technology offers a return on investment over time by reducing waste and errors due to improved accuracy. Automation has the potential to dramatically improve your business’s capabilities both now and in the future. With its capacity for integrating machine learning into its systems, it can become even smarter in anticipating demand and understanding customer requirements – taking your business to new heights in terms of speed, quantity, cost-effectiveness, and overall success.

Outsource non-core functions

Outsourcing non-core functions can be an effective way to free up resources and focus on your core competencies. Working with a partner specializing in specific processes can save time and money while maximizing efficiency throughout your company. Your partner will bring in the best people and technology for tasks that may fall outside your expertise. Whether it’s product design, material procurement, quality assurance, supply chain management, or other tasks, working with the right expert means that resources are not tied up on non-essential production functions.

The right outsourcing partners will take on some of your workloads so that you can grow your business faster than if you were doing everything internally. Plus, they often consult with leading industry professionals to ensure the work is completed in line with current industry standards and best practices. As a result, partnering with experienced outsourced vendors is an ideal way to keep production running smoothly while freeing up valuable internal resources. This can help your business stay agile as you move into the future and adapt to changing market conditions.

Outsourcing also gives you access to global markets; working with experts overseas may open up new opportunities for growth that would otherwise be out of reach due to cost or time constraints. With the advantages offered by outsourced partners now available to manufacturing businesses at competitive prices, there has never been a better time to explore alternatives for managing your operations.

Using energy-efficient machinery and equipment, automation, and outsourcing are excellent strategies for streamlining your manufacturing business and freeing up valuable resources. By implementing these strategies, you’ll be able to focus on your core competencies and achieve greater success in the future.