Rigid PCBs are something you will encounter almost everywhere. Their applications range from small electrical devices to large aerospace, military, and medical fields. Next, if we talk about ‘Flexible PCBs,’ they are built of the flexible substrate as opposed to rigid PCBs and have more advantages too. They have a lower thickness, have lighter weight, are dynamically bendable, can save space, and are more accessible for 3D interconnection assembly. They also have equally broad applications because of their excellent electrical and thermal performance.

The next dominant type is the ‘Flex-Rigid PCB,” built through further development and optimization of flexible PCBs. We will discuss the properties, manufacturing, and applications of Flex-rigid PCBs. But first, let us generally describe Rigid-flex PCBs.

What are Flex-rigid PCBs?

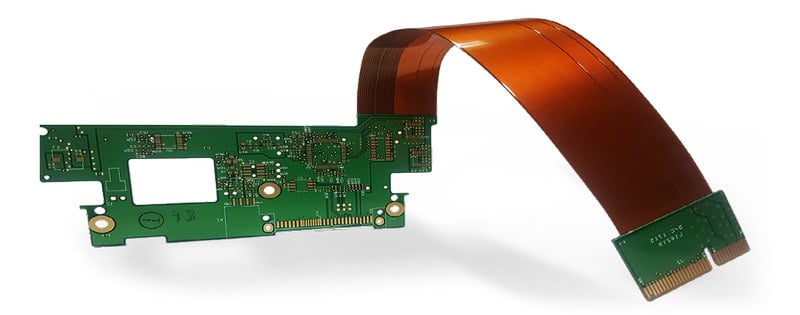

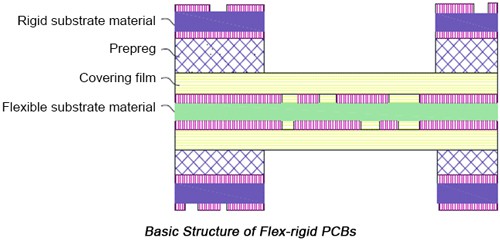

Flex-rigid PCBs are boards using a combination of flexible and rigid board technology. They consist of multiple layers of flexible circuit substrates attached to one or more rigid boards either externally or internally.

Types of material used in Flex-rigid PCBs

The substrate material is what gives the flex-rigid PCB its properties. It usually contains a flexible dielectric film and a flexible adhesive film.

1: Flexible Dielectric: The flexible dielectric film mainly includes polyester, polyimide, and fluoropolymer. Polyimide is the most common type and has the highest dielectric constant and excellent electrical plus mechanical properties and shows resistance to high temperatures. Polyester, on the other hand, does not show good resistive properties to high heat. The fluoropolymer is used in high-frequency applications such as military and aerospace products and has a low dielectric constant.

2: Flexible Adhesive film: The adhesive film mainly includes acrylic acid, epoxy, and polyester. Acrylic acid and polyester show high adhesion, flexibility, and heat resistance. However, due to its large coefficient of thermal expansion, it should not be over 0.5 mm thick. Epoxy shows bad adhesion and is mainly used in sticking the covering and internal layers.

Manufacturing of Flex-Rigid PCBs

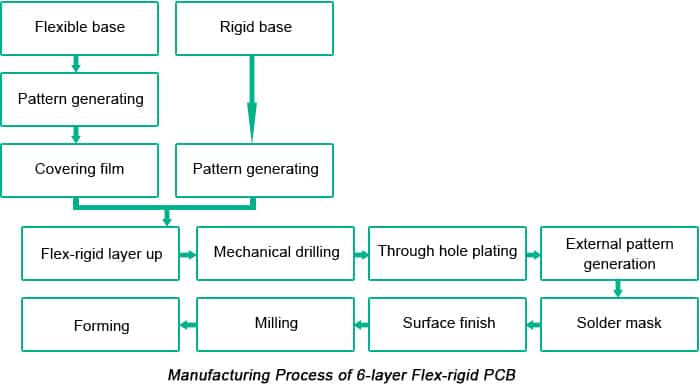

The manufacturing technology varies for each type of PCB. The most popular advanced PCB boards include HDI flex-rigid PCBs and embedded flex-rigid PCBs. The essential difference is the fine circuit manufacturing tech and micro-via manufacturing.

1: Flex-Rigid PCB Manufacturing

Flex-rigid PCBs are built using layers of rigid and flexible PCBs with plated through holes between them. Flex-rigid PCBs help to reduce the volume and heat problems caused by replacing harness and connectors.

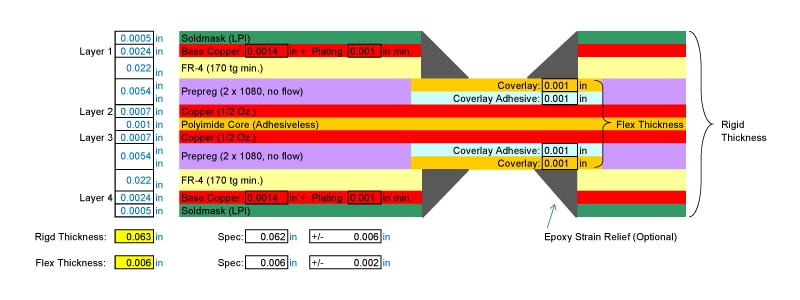

Formerly in the 1970s, Flex-rigid PCBs were built by stacking rigid board onto the flexible board. Today they are manufactured by using glass fiber epoxy resin (FR4) as an external rigid board on which solder mask is applied to protect the PCB. For the flexible substrate, polyimide double-layer board is used as a core, and a polyimide/acrylic film is used to protect the circuit pattern. The adhesion depends on the low-flow prepreg. In the end, the PCB is laminated to give the final result.

Flex-rigid PCBs have excellent electrical performance and mechanical properties, making them accessible for 3D assembly. They are perfect for use in devices that need to be bent. The flexible substrate is what makes it fit for high-frequency signal transmission and impedance control while resisting high temperatures and extreme environment effects.

These PCBs are hard to manufacture and repair. During manufacturing, the rigid base is embedded into the expensive flexible substrate material, so the raw material waste is high and the manufacturing difficulty.

2: Embedded Flexible PCB Manufacturing

Embedded flexible PCBs are manufactured by embedding flexible circuit units into rigid internal boards and so on. The connections usually depend on blind and buried vias as interconnections are unavailable. These PCBs contain the advantages of HDI and rigid PCBs and also reduce substrate material waste.

Embedded flux PCBs are manufactured by embedding flexible circuits and then layering. The flexible substrate material usage is increased for flexible circuit units. No electrical connections are available between flexible and rigid circuits in the same layer. Embedded flexible PCBs help to increase flexible substrate usage rate as the substrate material waste is reduced.

Order PCB Manufacturing Service Online Today

Sign up and get $20 coupon for free

Our Online PCB Quote and Order System allow you to get PCB production price within seconds. Click Here to Visit our quote page, and then fill in your circuit specification. If your high-density PCB project requires specifications not listed in quote page, feel free to reach us for solutions.